MICRO BURRAWAY: DEBURRING THE SMALLEST DRILL DIAMETERS

Front and back deburring & chamfering of smallest bores from Ø 1.00 mm

FEATURES OF THE MICRO-BURRAWAY

- designed for the smallest bores from 1.00 mm in diameter

- suitable for metric and inch bores

- suitable for all common tool holders

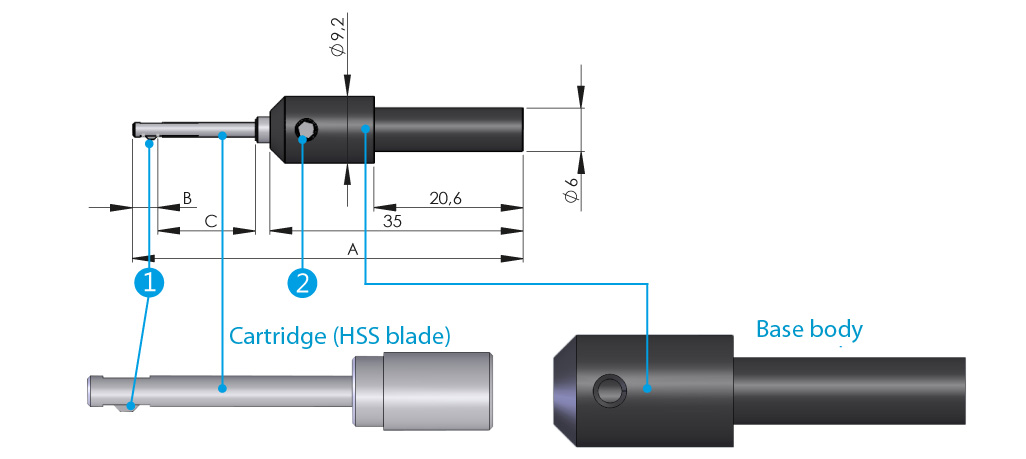

- easy handling due to two-part construction consisting of an cartridge (HSS blade) and base body

- simple functional principle of the burraway

- quick and easy change of the cartridge

The two-piece design allows you to replace the cartridge in seconds while the tool is still in the spindle. Each cartridge has an HSS blade that allows you to deburr countless bores before the holder needs to be replaced. The special surface of the blade does not damage the inner surface of the bore.

Do you have questions?

Please give us a call or fill out our contact form!

APPLICATION AREAS

Applications in the medical, automotive and electrical industries require more and more machining and deburring of very small bores.

The new Micro Burraway has been developed for this type of application and can deburr the front and back of even the smallest bores from 1.00 mm diameter in a single operation.The tool is applicable for materials such as aluminum, steel, stainless steel, titanium and even composite materials.

The Micro Burraway series features a flexible blade that retracts into the mandrel to adjust to the bore diameter. The tool is composed of the low-cost, interchangeable cartridges (in a variety of sizes) with an integrated blade and a standard base body that has a 6 mm shank, making it easy to put it into a variety of tool holders.

Two types of blades are offered; One is a DA (Dual Acting) blade, which ensures front and back deburring in one operation. On the other hand, we offer a BA blade (Back Acting), which only deburrs the back side of the workpiece. The front side is then rounded.