IBEX DEBURRING SYSTEM: TOOL FOR DEBURRING EVEN UNDEFINED CONTOURS

Tool for deburring even undefined contours

Video 1: Deburring without programmed correction

Video 2: Deburring of gear flanks

Video 3: Deburring a cast component

Video 4: Deburring of extruded aluminum profiles

The ibex deburring system - consisting of compensation holder and cutter

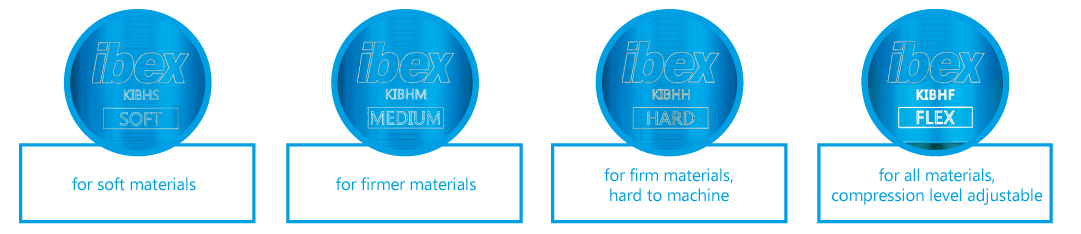

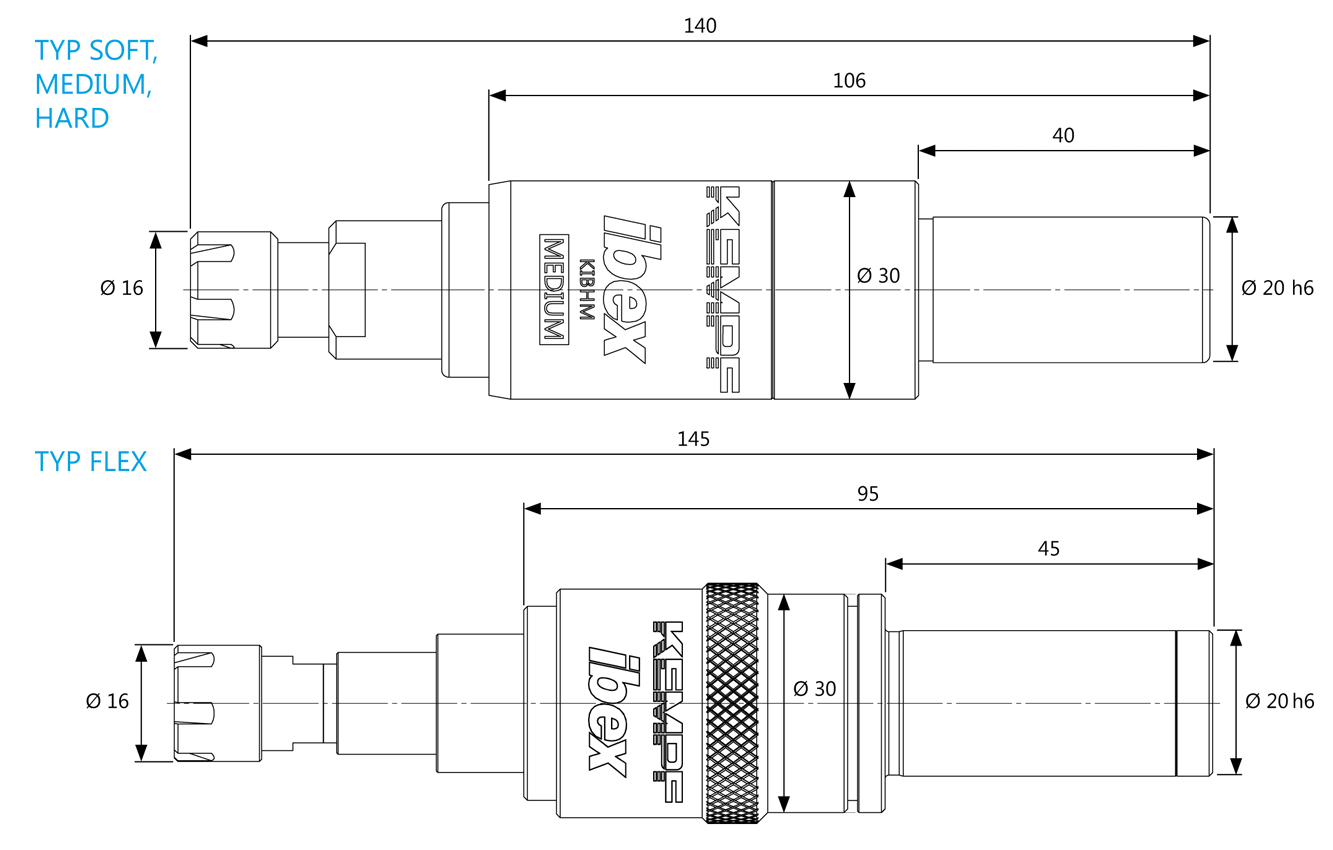

IBEX COMPENSATION HOLDER - 4 TYPES

Features

| IBEX SOFT, MEDIUM & HARD | NEW! IBEX FLEX |

|

|

IBEX DEBURRING CUTTER

- Low chatter due to specially developed cutter geometry

- Extremely high tool life of the cutters due to special geometry

- High feed rates due to cross-cut grinding

Are you interested in our ibex system or do you have questions?

Please give us a call or fill out our contact form!

Inspired by nature and implemented on the machine - the ibex deburring system.

The Ibex (Capricorn) is perfectly adapted to its environment. Thanks to its special hooves, for example, it finds a good grip even on the steepest terrain and can jump several meters high from a standing position, thus overcoming rocky edges or crevices with ease. The Ibex is a master when it comes to moving where there is no progress for others. No matter what kind of ground - the Ibex is not called "The King of the Mountains" for nothing.

Agile - in impassable components

We have taken these properties as a model and developed the "KEMPF ibex". Wherever edges have to be deburred, the innovative compensation holder is used and shows its strengths. Due to the high flexibility and the possibility to deburr with tension and pressure compensation, the clamped milling cutter can adapt to any component geometry and thus also deburrs undefined edges cleanly, process-safe and evenly. Downstream manual deburring is no longer necessary.

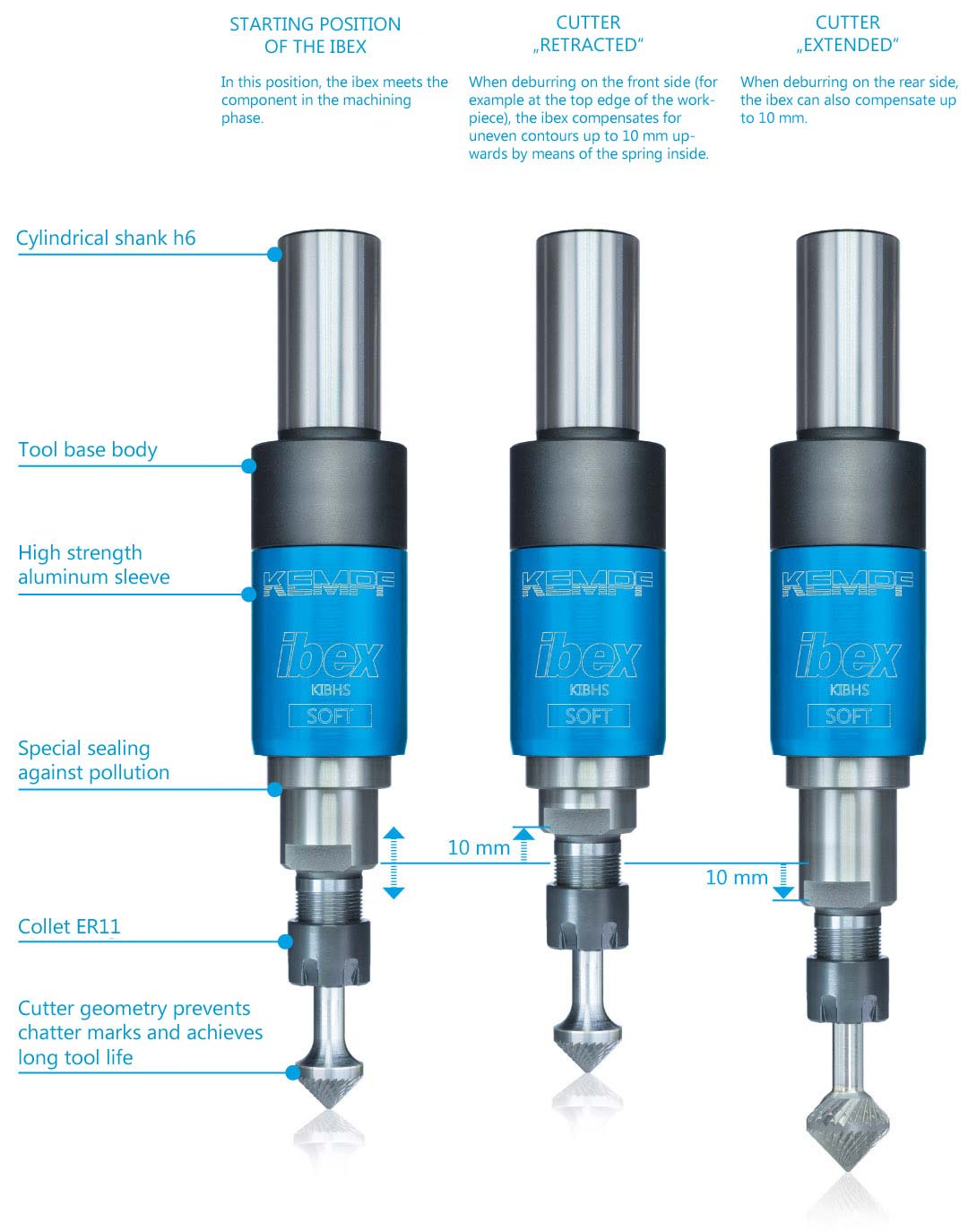

CONSTRUCTION OF THE IBEX DEBURRING SYSTEM (SOFT, MEDIUM, HARD)

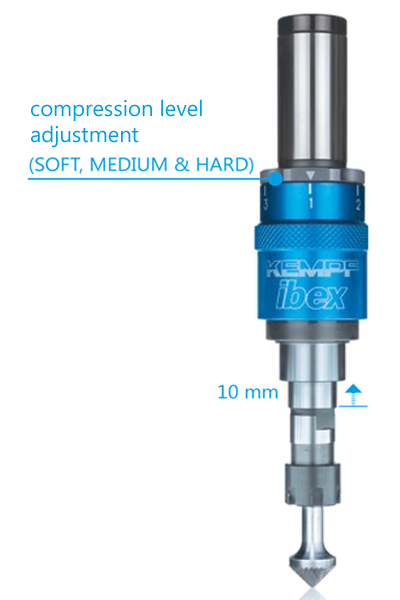

CONSTRUCTION OF THE IBEX FLEX

|

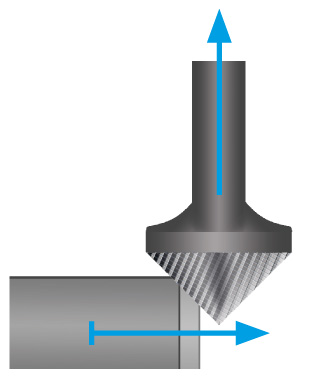

As soon as the cutter hits the edge of the workpiece, it can perform the axial movement due to the linear mounted compensation of the ibex. In interaction with the tapered ibex deburring cutters, radial dimensional deviations of the component can also be compensated. Thus, the deburring cutter always has the same cutting performance on the workpiece and produces uniform deburring. |

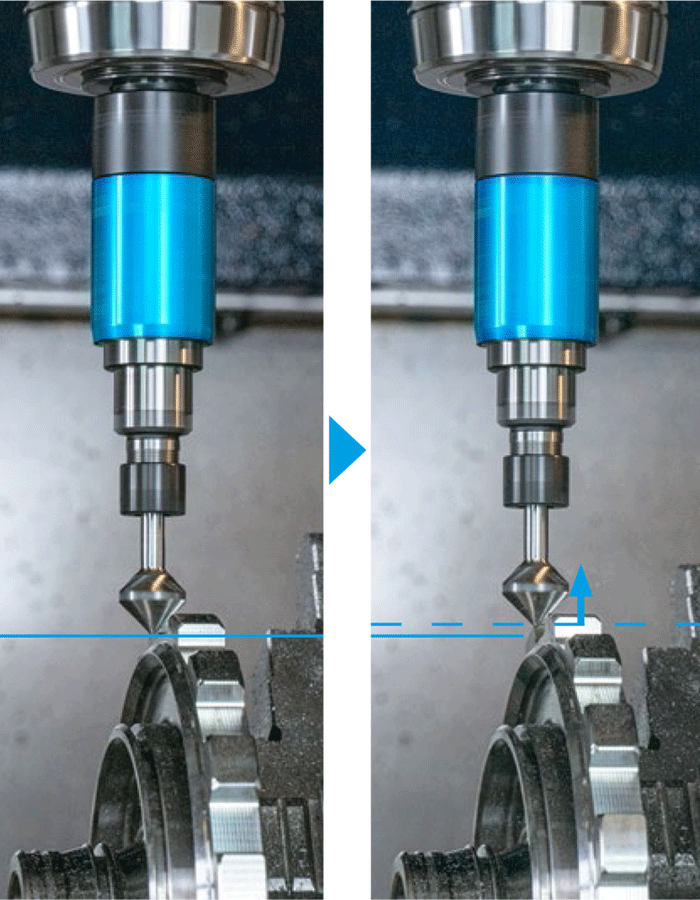

EXAMPLE "SHAFT OF AN AUTOMATIC TRANSMISSION"

|

In the starting position the deburring cutter meets the contour which has to be deburred. The cutter is pushed upwards. The ibex compensates this movement and makes the cutter move back to the starting position after the deburring cycle as fast as possible |

|

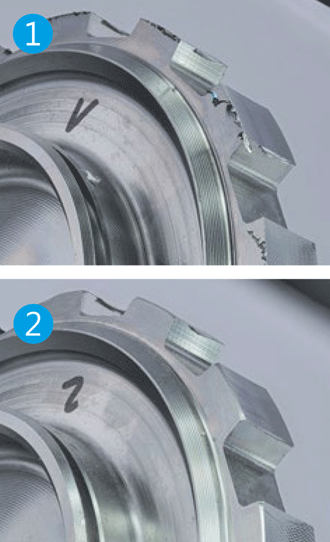

1. BEFORE:

|