Special tools

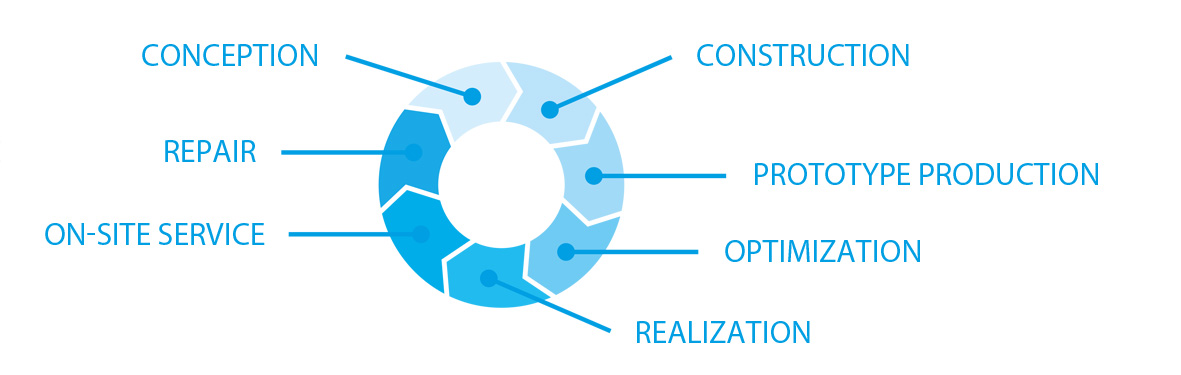

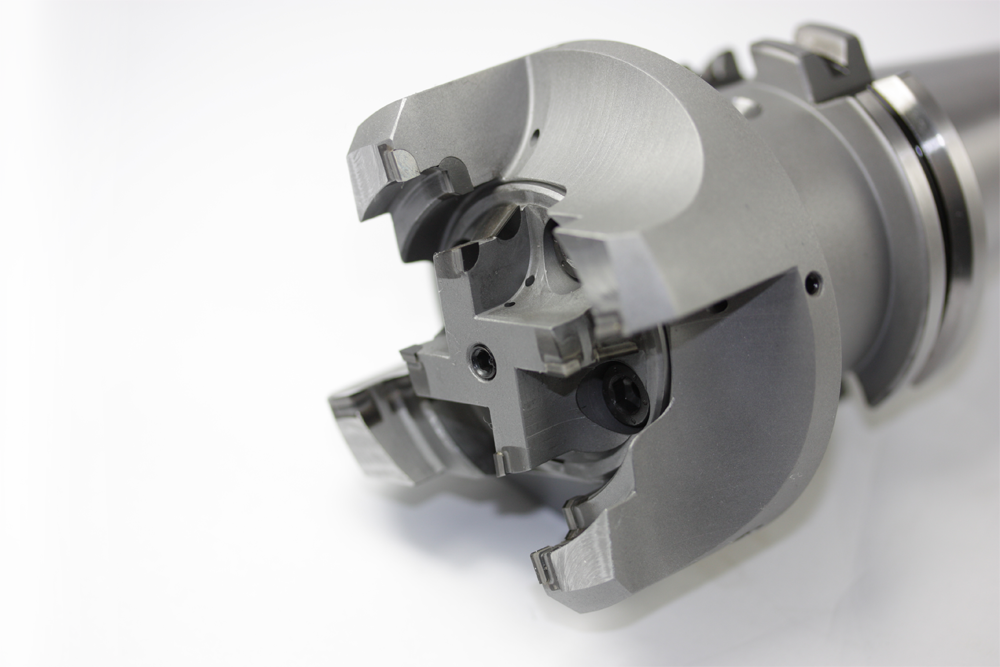

In order to meet the demands for increasingly complicated components with extremely tight tolerances, innovative special tools are required. As a specialist for special tools, our team of machinists and technicians develops individual special solutions for you and your application. Due to our many years of know-how in the field of cutting tools, we are able to design and construct special tools for the most difficult machining tasks. This allows us to offer you the right tooling solution for almost any machining process - quickly, cost-effectively and in the best KEMPF-quality.

Since holistic support is very important to us, we not only take care of product tests and measurements, but also offer repair and regrinding (or re-lasering) services. Everything from one source - just as it should be with a good partner.

Since holistic support is very important to us, we not only take care of product tests and measurements, but also offer repair and regrinding (or re-lasering) services. Everything from one source - just as it should be with a good partner.

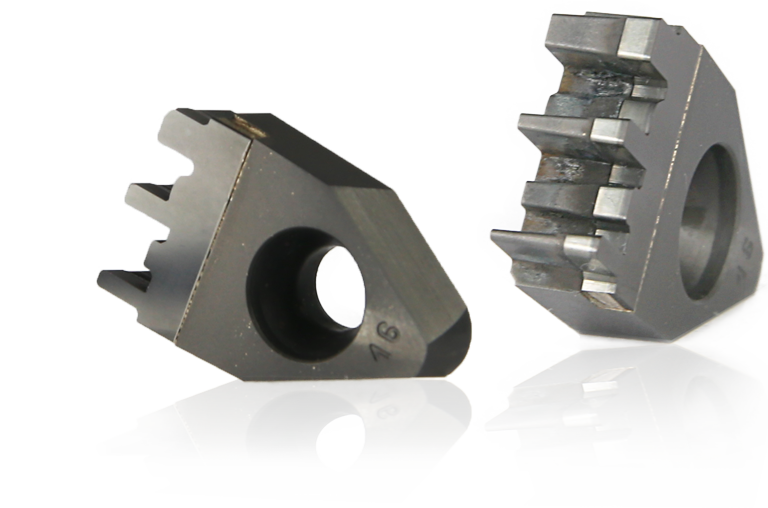

TOOLS WITH DIAMOND TIPPING

DIAMOND TIPPING

Since the range of solid carbide tools reaches its limits for certain materials and machining processes, we also offer PCD-, CBN- and MCD-tipped tool solutions. Therefore, we not only assume of the design, but also the maintenance/repair service. Convince yourself of our price-performance ratio made by KEMPF.

PCD, CBN and MCD tipped tools are the most economical solution in machining with geometrically specific cutting edge. With no other cutting material can you achieve such outstanding cutting results. Thereby, each special tool is aligned to the required machining case. With the tool solutions by KEMPF you achieve high application parameters in connection with a high process reliability. Our finely balanced tools achieve very high cutting speeds and feed rates. The achieved bore accuracies and surface qualities are excellent.

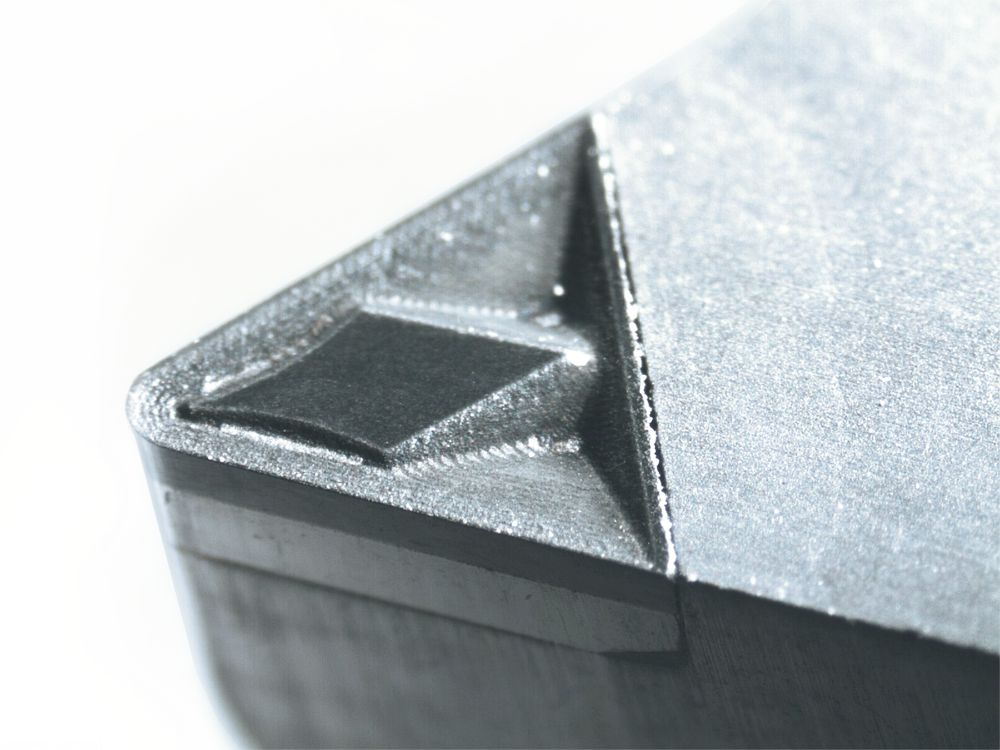

3D LASERED CHIP GUIDES

Laser cutting can also be used, for example, to create such complex 3D-lasered chip guides for optimum cutting performance and chip breaking. This would not be possible in this fineness with standard wire EDM.

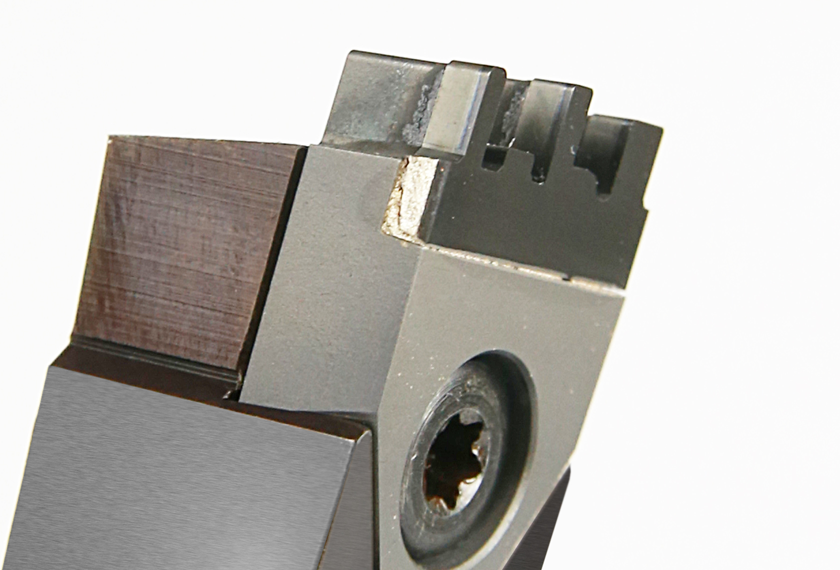

LASERED CUTTING EDGES FOR HIGHEST PRECISION

Quality made in Germany - this is also evident in the manufacture of the blades. Because these are manufactured with the highest precision as standard. When the PCD or MCD cutting edges are lasered, the grains of the cutting material are not "ripped out" but cleanly separated, opposed to ground cutting edges, so that absolutely smooth and thus sharp cutting edges are produced.

- 3D lasered chip guides and chip breakers

-

Laser processing makes it possible to produce a larger substructure, which results in more stability and less

vibrations - Increased number of cutting edges on the tool possible due to adjustable machining depth of the laser

- As opposed to EDM, corner radiuses of < 0.05 are possible with laser processing

- Even the most complicated contours are realizable

We offer a relasering or regrinding and repair service for our own and third-party tools.

You can find more information in our catalog SPECIALTOOLS IN PRECISION

You can also find a detailed overview of our whole product portfolio in our online and print catalogs »

Do you have questions?

Please give us a call or fill out our contact form!