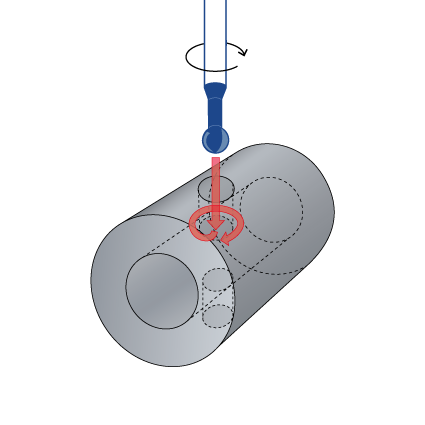

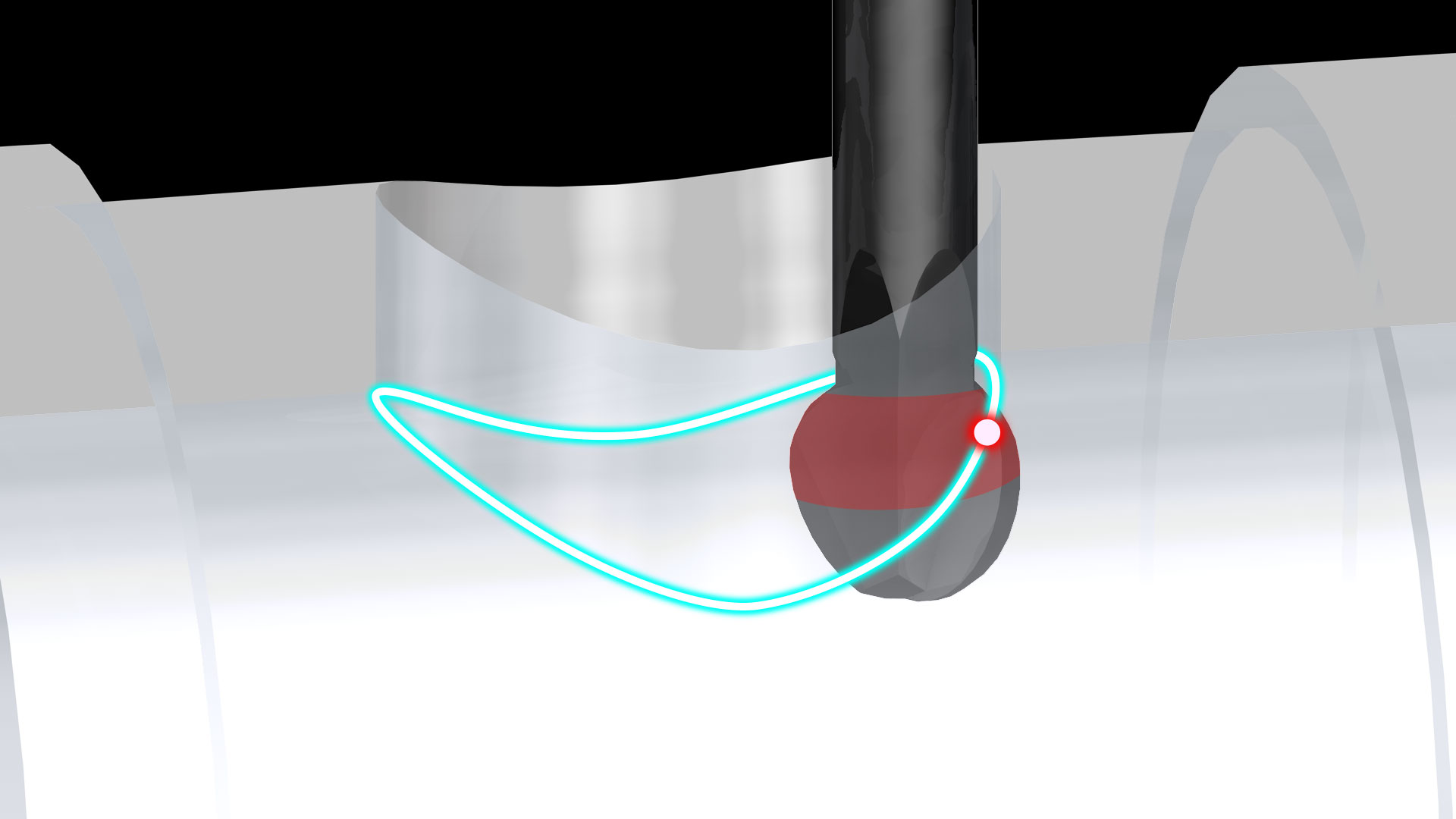

BACK BURR CUTTER & PATH: DEBURRING SYSTEM FOR CURVED EDGES

Front and back deburring of edges on 3D curved surfaces

|

SPECIAL DEVELOPED DEBURRING CUTTER

NC-DATASET (PATH)

|

|

|

Do you have questions? |

|

|

|

|

For CNC deburring, basically only two types of tool solutions are offered on the market. For the most part, these are tools that perform linear movements in relation to the cross hole and rotate in the process. A more effective variant is machining with a ball cutter, which deburrs along the edge to be machined at two intersecting holes parallel to the contour.

|

|

|

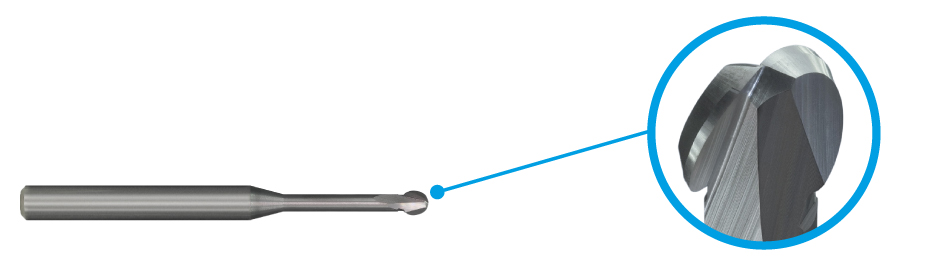

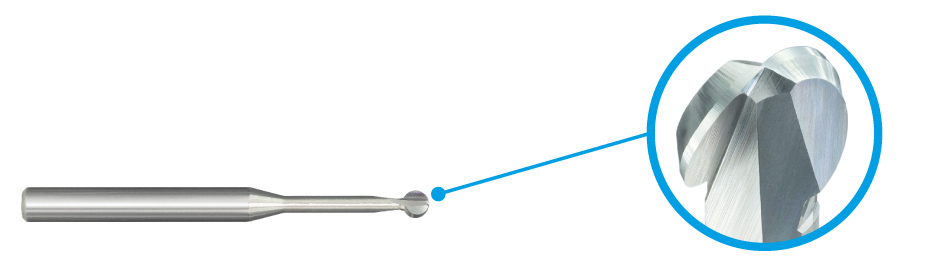

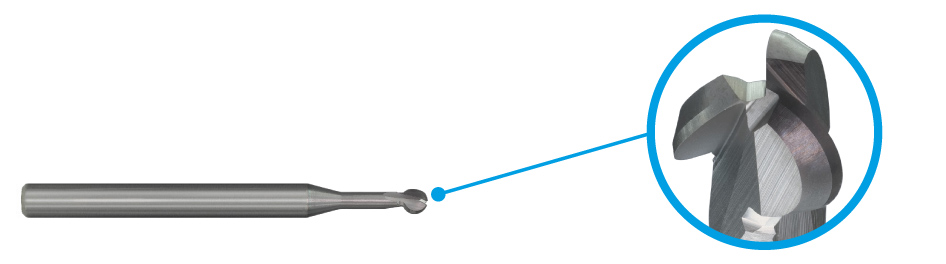

However, even with these tools, which are far more flexible to use, difficulties arise when programming the data sets of the contour to be machined. It is precisely these problems that the development team from Xebec in Japan has addressed and developed a holistic tool solution that enables high-quality CNC bore deburring. The Back-Burr Cutter & Path deburring system is subject to constant further development. In order to be able to use the deburring system as universally as possible, the tool itself is also subject to continuous innovations. In addition to the previous variants with continuous and stepped shank, the program has now been expanded with two further variants, so that currently 4 versions of the Back-Burr Cutter are available. Please note: Please inquire about the new Back-Burr Cutter Type A-N and AS-3F only by phone or e-mail.

|

|

|

TYP A

|

|

|

TYP A-N

|

|

|

TYP AS-3F

|

|

|

TYP B

|

|

|

|

The Xebec Back-Burr Cutter is an innovative bore deburring solution that is a synergy of the cutter and the NC data set (path), as both components are perfectly matched and the tool is optimally used. Due to the individual creation of the data set, the milling cutter traces the contour of the component to be deburred with high precision and thus removes burrs safely and without leaving any residue - even on the back side of bores. |

|

In principle, it is irrelevant which contour shape is to be deburred. The coordinate points of the NC data set are used to program a customized path for each application and to optimize the use of the tool, taking into account the machining points, contact points and cutter angles. Thanks to the machining program, a cutter is usually sufficient to deburr various bore diameters. The supplied data set not only describes simple (round) bore edges, but also offers much more machining capabilities, since orthogonal transverse bores as well as angled, interrupted bores and bores with openings can also be machined. The user thus usually only has to use a single tool for many machining variants, so that the machining time is reduced by a multiple. In addition, the cutting point of the cutter can also be shifted during contour machining, so that the cutting edge is more evenly stressed on the one hand and the tool life is significantly increased on the other. |

|

| KEMPF MEDIA-SECTION | |