FLIP-CUT: CHAMFERING TOOL AND COUNTERSINK

For back facing as well as for front and back chamfering in one operation with only one tool

FEATURES OF THE FLIPCUT

- Precise chamfering and countersinking with one tool in one set-up

- The special cutting edge geometry ensures a forced folding back of the cutting edge

- The use of carbide-tipped cutting edges ensures a long tool life and economical machining

- Internal coolant supply ensures metall shavings removal and guarantees an optimum folding in and out of the carbide cutting edge

- Standard tools are available from Ø 7.0 mm to Ø 34.0 mm

- Standard cutting edges are available for back-side facing and front-side chamfering, as well as for back- and front-side chamfering

Do you have questions?

Please give us a call or fill out our contact form!

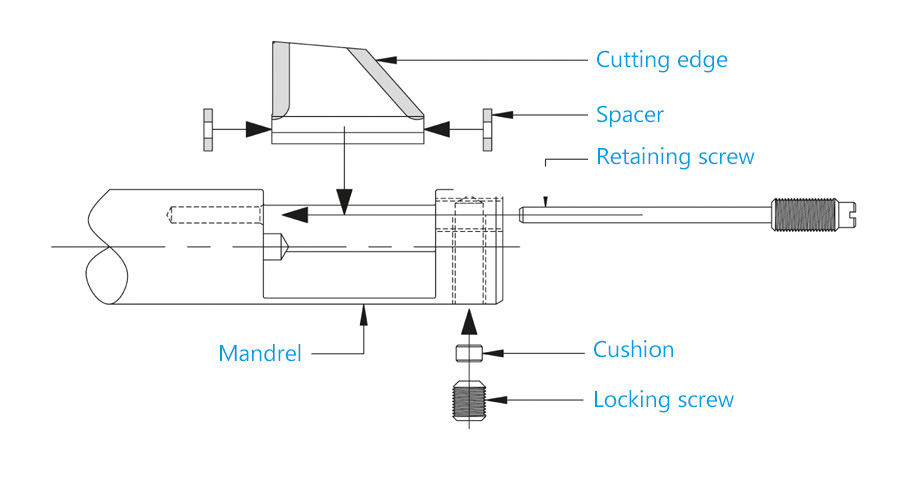

The FLIPCUT consists of only five parts that allow easy handling.

The cutting edges are tipped with carbide and thus prevent thermal expansion, so that the folding of the cutting edges is always guaranteed. In case of abrasion, the cutting edge can be replaced quickly and easily.

|

1. FRONT BEVEL MACHINING In spindle clockwise rotation the knife is extended and can produce the front bevel. |

|

2. BORE TRAVERSING Switch spindle rotation to counter-clockwise and plunge into the hole at maximum feed |

|

3. CHAMFERING BACK SIDE In clockwise rotation, the rear face countersink is created. The depth of the countersink can be selected individually. |

|

Switch spindle direction to counter-clockwise and plunge into the hole at maximum feed (approx. 0.20mm/rev). |