GMO DEBURRING TOOL FOR HARD-TO-REACH HOLES

Precise deburring of flat surfaces and curved bore edges in difficult to access positions and for chamfering bore fronts and backs.

FEATURES OF THE GMO DEBURRING TOOL

- deburring process in seconds

- deburring of smallest bores from Ø 0.8mm

- rotating tool with carbide blade

- clean and reliable deburring process

- easy handling, no special requirements necessary

- can be used on any machine, ideal for use on CNC machines

- deburring strength is adjustable by adjusting screws or 4 different springs

- Patented tool system

The tool can be used with spring force, but also with rigid adjustment. See Functionality.

Our GMO Deburring Tools simulations und programming support

Do you have questions?

Please give us a call or fill out our contact form!

The GMO deburring tool is designed for bores from diameter 0.8 mm. Individual components can be changed quickly and easily for different workpiece diameters. With 4 different types of pressure springs (light, medium, strong and very strong) it is also possible to regulate the contact pressure of the tool against the workpiece. An adjusting screw can be used to limit the swing-out dimension of the blade or to set it exactly to the diameter to be deburred. Blades in various designs are available for the tool.

For example, not only inner edges but also outer edges and strongly curved workpiece surfaces can be deburred.

|

Deburring of bores with curved bore edges |

|

|

|

|

|

Deburring of bores in difficult to access positions |

|

| With the GMO deburring tool, bores can be deburred using two machining methods. In most cases, it is sufficient to work with the spring force of the inserted pressure spring. In addition, the pressure spring can also be replaced by an M3 screw so that defined chamfers can be created or larger burrs removed in a rigid setting. This is useful for threaded holes, for example. Regardless of the hosen machining option, the tool must be assembled and adjusted so that the centre of the front Blade meets the edge of the hole, depending on the diameter of the hole to be deburred. |

||

|

DEBURRING WITH SPRING FORCE Various pressure springs with different pressure forces are available. |

||

|

|

|

|

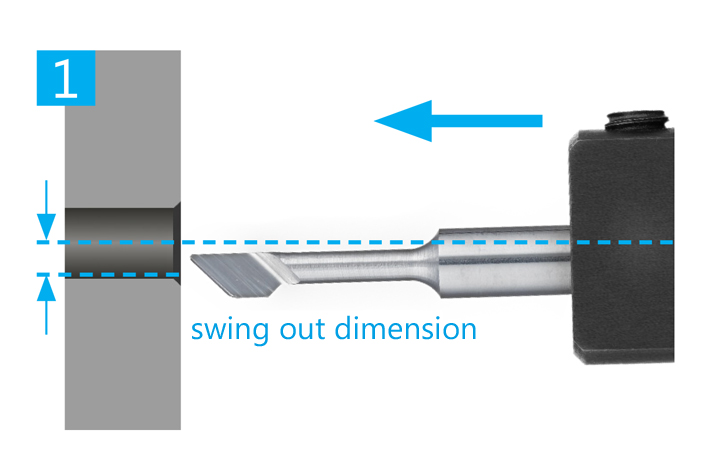

DRIVE IN Position the centre axis of the deburring tool on the centre of the bore. Adjust the swing-out dimension so that the centre of the Blade meets the edge of the hole. |

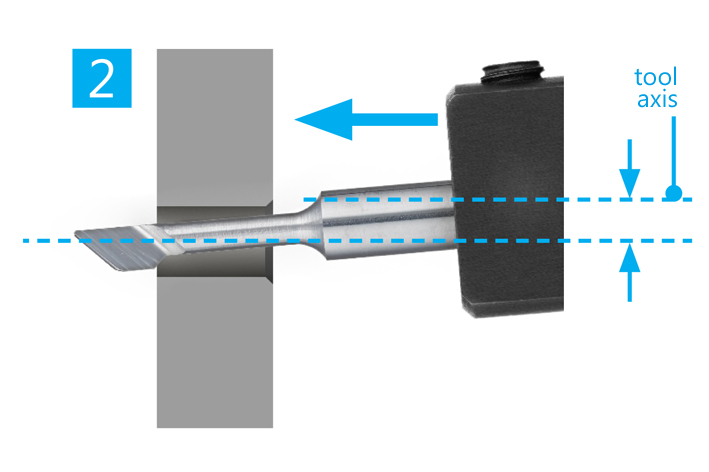

DRIVE THROUGH THE BORE Drive into the hole with the tool rotating and at a high feed rate (approx. F=500). |

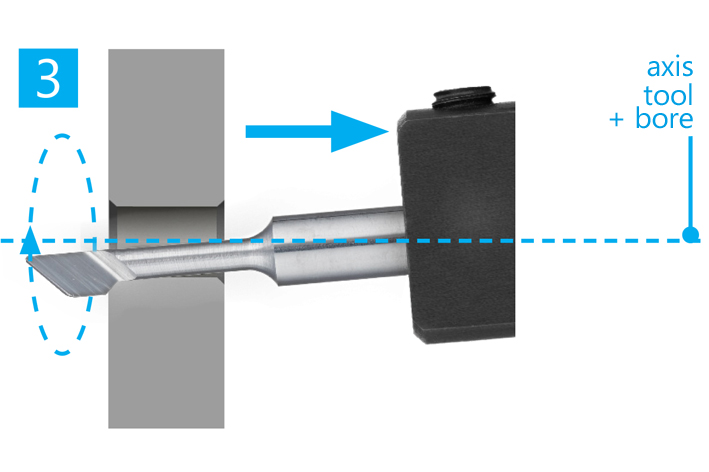

DEBURRING THE BACK OF THE HOLE Only drive in until the tool swings outwards and the offset tool neck rests against the hole. |

|

DEBURRING WITH RIGID SETTING The spring is removed and replaced by the enclosed M3 screw. The swing-out dimension is now precisely adjusted and fixed with two screws. With the help of the tool simulation and the free programming support, optimal machine programming is possible. |

||

|

|

|

|

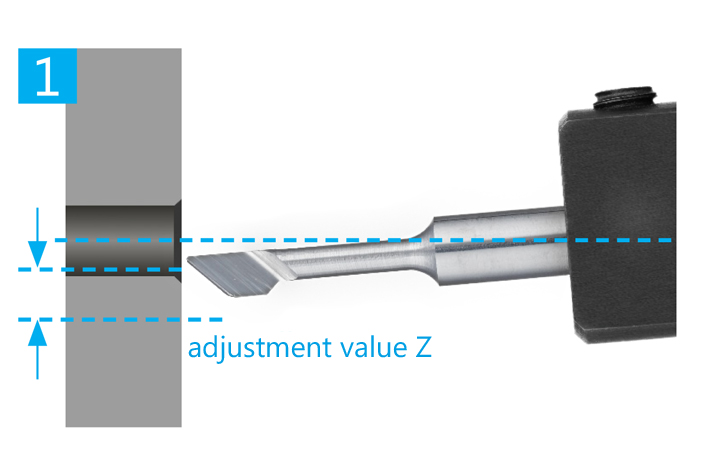

ADJUSTING THE BLADE. Position the centre axis of the deburring tool on the centre of the hole. Adjust the swing-out dimension so that the centre of the blade meets the edge of the hole. |

TRAVERSING THE HOLE After adjusting the blade, drive rapidly through the hole without rotation. |

ADJUSTING THE BLADE Then reset the spindle or the workpiece by the adjustment value. Now switch on the rotation and move slowly upwards until the desired chamfer is reached.

|