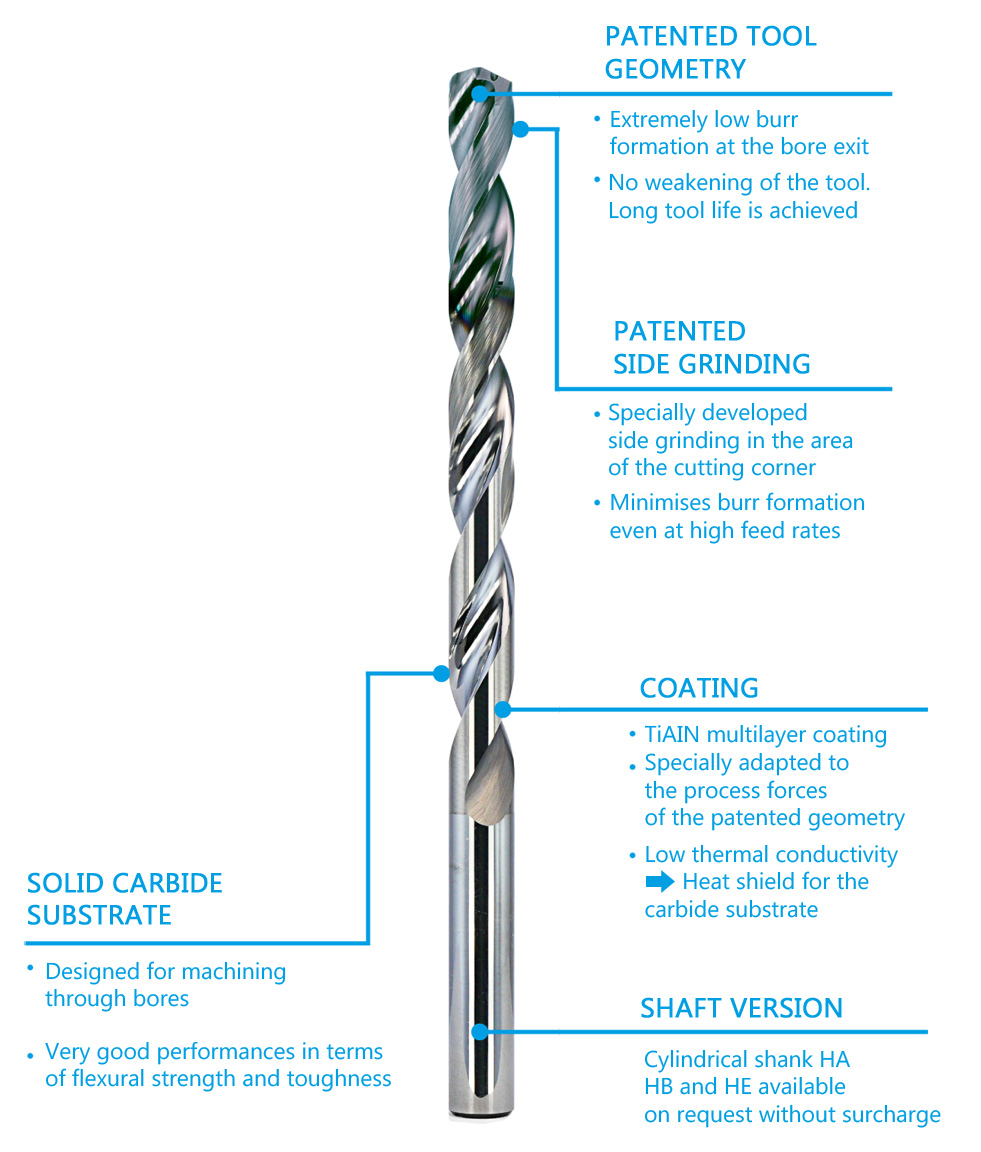

EXBURRDRILL: BURR-MINIMAL & "BURR-FREE" DRILLING

Solid carbide drill for the production of burr-minimal bore exits

|

MINIMUM BURR WITH MAXIMUM FEED The new KEMPF solid carbide ExBurrDrill sets standards in the field of burr minimization - without compromising on feed. We manufacture the KEMPF ExBurrDrill in special dimensions for your application In order to achieve a burr-minimizing bore machining, we manufacture the KEMPF ExBurr Drill individually for your application. Taking into account the conditions on your component and the material, the tool geometry of the ExBurrDrill is designed in a parameterized manner. |

|

|

|

|

We will be pleased to manufacture the KEMPF ExBurrDrill for you in the diameter ranges from Ø 1.0 mm to Ø 20.00 mm, with or without internal cooling (IC), as well as a step drill variant (StuBo). We will be pleased to manufacture the KEMPF ExBurrDrill for you in the diameter ranges from Ø 1.0 mm to Ø 20.00 mm, with or without internal cooling (IC), as well as a step drill variant (StuBo). |

|

When exit burrs must be avoided, the new solid carbide drill for burr-minimal drilling has clear advantages.

Thanks to its special and patented tool geometry, burr formation at the hole exit is reduced to a minimum. By using the new drill...

- a downstream process for deburring becomes superfluous. This minimizes process and, if necessary, setup costs and reduces the machining time of the component.

If very high requirements are made on the burr-free quality of a component...

process-reliable, downstream burr machining is possible.

The burr root of the exit burr is minimized. The downstream deburring tool can thus shear off the burr root in a process-safe manner.

The tool life of the deburring tool is multiplied.

|

BURR-MINIMAL, FAST & DURABLE With the KEMPF ExBurrDrill, a tool development has succeeded which enables burr-minimal drilling without any losses in terms of tool life and process speeds. |

|

|

|