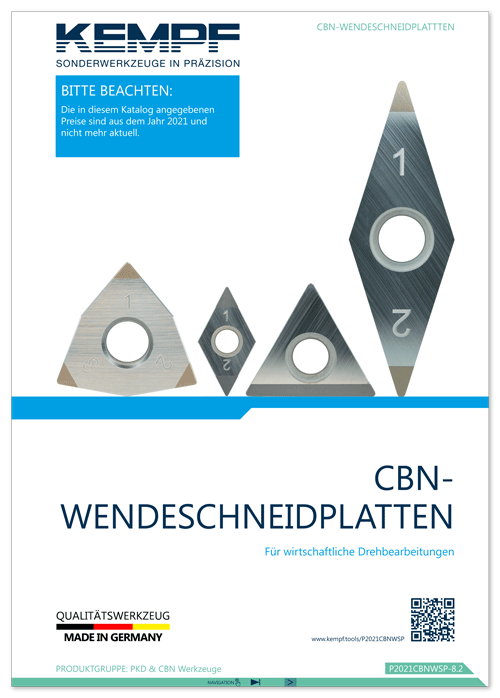

CBN indexable inserts

Hard and hardened iron materials from 40 to 70 HRc can be machined most economically with tools made of CBN (cubic boron nitride) – the second-hardest cutting material after synthetic diamond. CBN is very resistant to deformation and flank wear, is extremely fracture-resistant and chemically stable - for high resistance to diffusion and oxidation. The cutting material also has an extreme hot hardness in order to be able to act reliably in cutting zone temperatures between 250°C and 1000°C, which are required depending on the material. For high-performance machining in all areas, we offer high-precision and durable indexable inserts in a large selection of geometries and blade variants.

You can also find a detailed overview of our products in our catalog:

Do you have questions? Please give us a call or fill out our contact form!