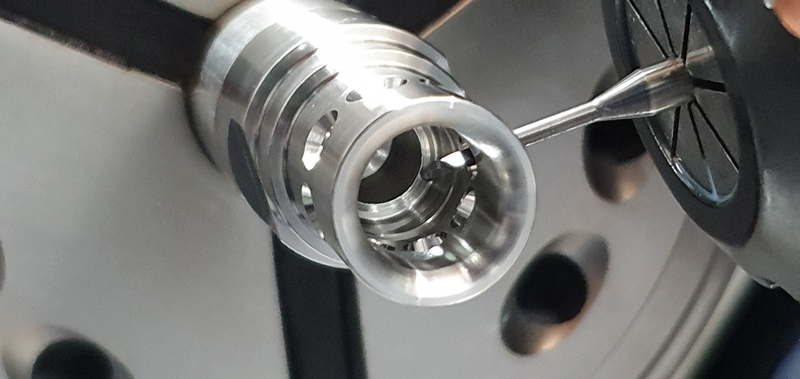

Once again, we were able to impress a customer with the innovative Back-Burr Cutter & Path deburring system and provide a more than satisfactory tooling solution for a medical component made of 1.4404 stainless steel with 8 radial holes. Instead of 8 machining steps, which would have been necessary with a conventional reverse deburring tool, only 4 positioning operations were sufficient with the use of the deburring system.

Thanks to the NC data set we supplied, the machining could be programmed so that the special ball cutter could travel through the bores and thus also deburr the opposite contours. Resolving in machining time being cut by half, the quality was increased by clean and defined chamfers and finally the customer was made happy. What more could you want!

More about the award-winning Back-Burr Cutter & Path Deburring System